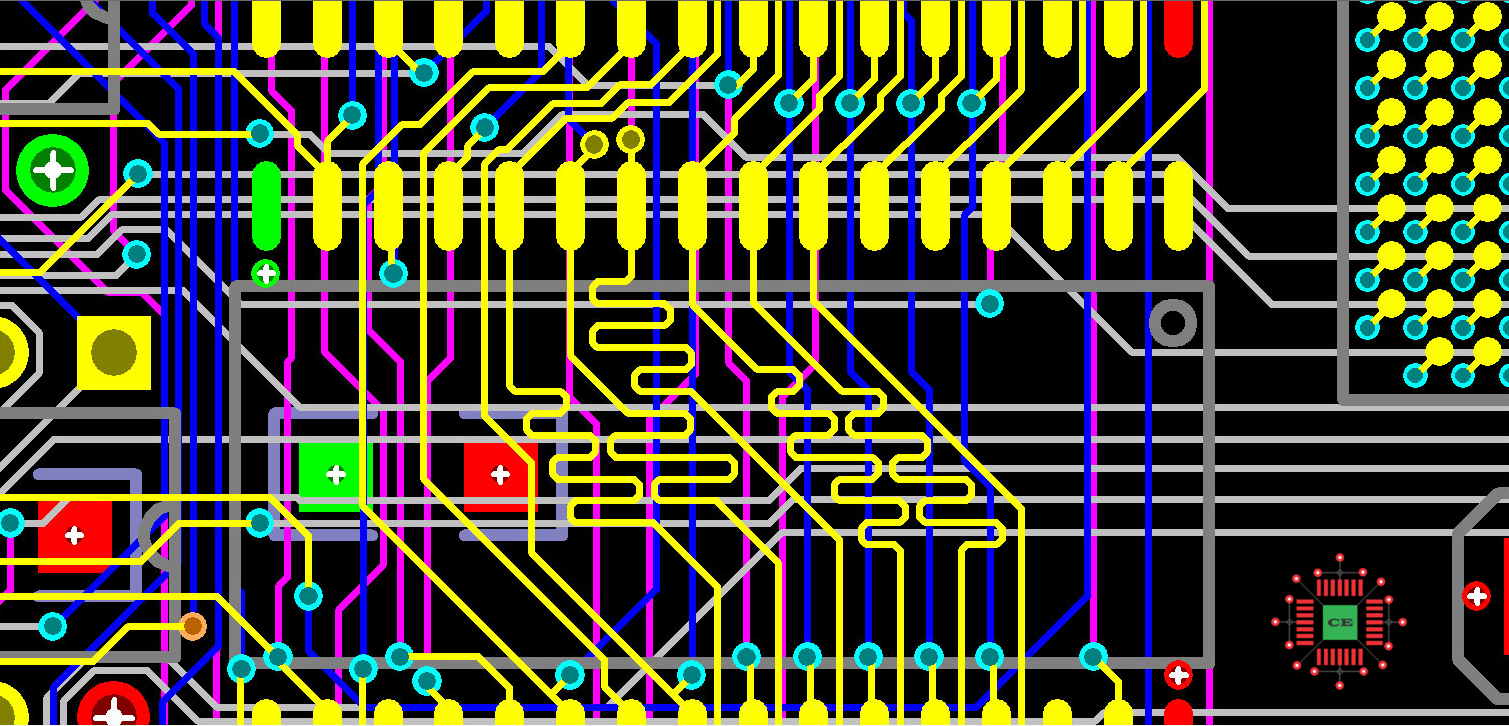

PCB Design Layout

Our PCB layout and PCB design services and capabilities includes

- Single-sided, double-sided, and multi-layer boards (up to 16 layers) with high density design handing capabilities.

- Component Library creation as per IPC standard.

- Design for Surface mount, through-hole & mixed technology with QFN,BGA, PGA & fine pitch components.

- Design as per EMI/EMC requirement.

- Design for manufacturability (DFM)

- Design for Assembly (DFA)

- Bill of material generation.

- Reverse Engineering (Bare board to design file/gerber)

- Gerber Generation

- Stack up creation for Multilayer.